We are Manufacturer, Supplier of Flat Gaskets, Heat Exchanger Gaskets, Rubber Gaskets, Metal Clad Gaskets, Compressed Asbestos Fibre Gaskets, Non Asbestos Gaskets, Mill Board Gaskets, Oil Resistant Rubber Cork Gaskets (Cork Gasket Material), Vulcanised Fibre Gaskets, Woolen Felt Gaskets (Wool Natural Felt Gaskets), Teflon Gaskets (PTFE Gaskets), Cut Gaskets, Ring Type Joints (RTJ Gaskets), Graphite Ring Gaskets and our setup is situated in Pune, Maharashtra, India. We majorly targeted customers from ALL OVER PUNE including (PCMC (Pimpri Chinchwad), Talawade, Narhe, Chakan, Bhosari, Talegaon, Ranjangaon), Nashik, Mumbai, Raigad, Aurangabad, Sangli, Kolhapur.

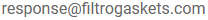

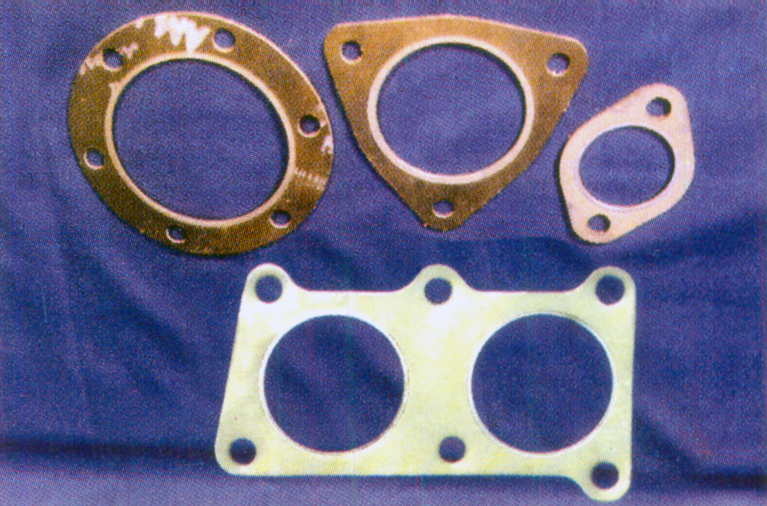

Flat Gaskets

Flat Gaskets used in Flanges ( Manufactured according to B.S. table, ANSI table ) Valves, Pumps, Gearboxes, All types of Engines, Gas Turbines, Compressors, Generators. Flat Gaskets are precision-cut sealing elements used to prevent leakage between two flat surfaces under compression. Commonly made from non-metallic materials like rubber, graphite, PTFE, or compressed fiber, they are ideal for low to medium pressure applications. These gaskets are widely used in pumps, valves, flanges, and pipeline systems across oil & gas, water treatment, and chemical industries. Their versatility, ease of installation, and cost-effectiveness make them suitable for static sealing under varying temperatures and pressures. Flat gaskets ensure tight, leak-proof seals, maintaining system integrity and minimizing maintenance in industrial operations.

Heat Exchanger Gaskets

Heat Exchanger Gaskets is used for Oil Coolers, Water Coolers, Boilers, Air Coolers, Radiators. Heat Exchanger Gaskets are specialized sealing components designed to withstand high pressure and temperature variations in plate and shell-and-tube heat exchangers. Made from materials like graphite, rubber, PTFE, or metal-reinforced composites, they provide excellent chemical and thermal resistance. These gaskets ensure efficient heat transfer while preventing internal and external leakage of fluids. Common applications include power plants, refineries, HVAC systems, and chemical processing units. Custom shapes and profiles allow them to fit precisely between plates or flanges, ensuring reliable sealing performance and easy replacement during maintenance cycles.

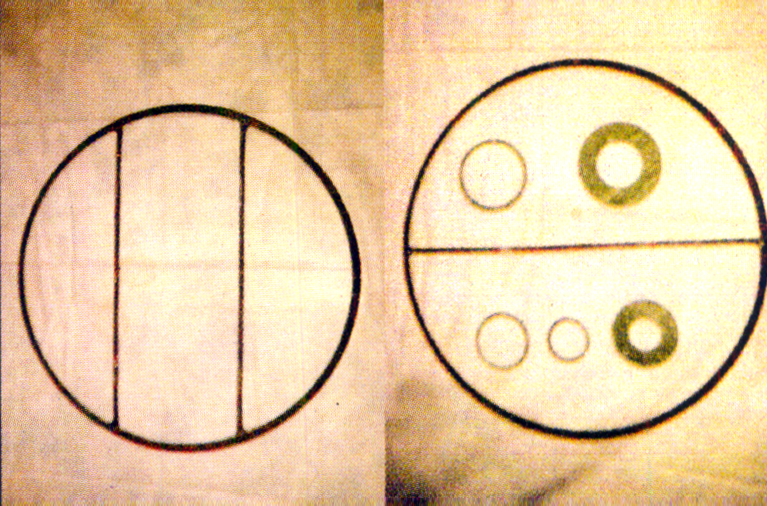

Rubber Gaskets

Rubber Gaskets Made from Natural Nitdle, Neoprene, Food Grade, EPDM. Generally used in Water and Waste Water Treatment Plants. Food Grade Rubber Gaskets used in Dairy Plants. Rubber Gaskets are flexible sealing solutions made from elastomers like EPDM, NBR (Nitrile), Neoprene, Silicone, and Viton. They offer excellent sealing, cushioning, and vibration resistance, making them ideal for automotive, plumbing, HVAC, and electrical enclosures. These gaskets conform easily to mating surfaces, ensuring a tight seal even under uneven loads or misalignments. Their weather resistance, chemical compatibility, and durability make them suitable for indoor and outdoor applications. Rubber gaskets are cost-effective, easy to install, and available in various thicknesses and shapes for both static and dynamic sealing requirements.

Metal Clad Gaskets

Metal Clad Gaskets, is the fusion of Robust Metal Layers interlace with precision sealing materials, fortifying connections against extreme conditions in industries from oil to aerospace. Asbestos covered fully or partially with metal like copper, steel. These are used in Exhaust System, Water Jackets. Metal Clad Gaskets combine the strength of a metal jacket with the sealing efficiency of a soft filler material like graphite, asbestos-free fiber, or PTFE. These gaskets are used in high-temperature and high-pressure environments such as boilers, heat exchangers, pipelines, and pressure vessels. The metal cladding (usually SS, CS, or Inconel) provides structural integrity, while the soft core enhances compressibility and sealing performance. Metal clad gaskets are preferred in critical sealing applications in oil & gas, petrochemical, and power generation industries. They ensure leak-proof performance under fluctuating loads and extreme thermal conditions.